-

Straight length hose

Acid & Chemical

-

Straight length hose

Air/Water

-

Straight length hose

Food Grade

-

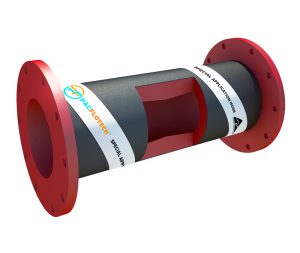

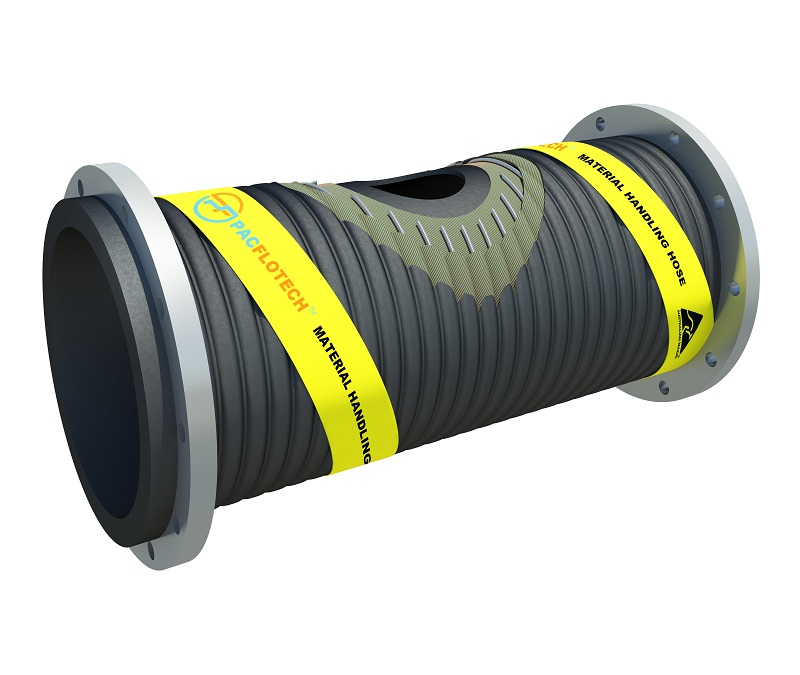

Straight length hose

Material Handling

Material Handling

| Size | DN 12-1200mm |

|---|---|

| Length | Up to 20mt (dependent on hose I.D) |

| Duty | Suction and discharge, discharge only (no wire reinforcement) |

| Max working pressure | -100 to + 8000kpa (dependant on hose I.D) |

| Reinforcement | Spiral synthetic fabric |

| Tube | ABRASATECH™, BUTATECH™ |

| Cover | Abrasion and UV resistant rubber |

| Ends | Beaded, Flanged, In Built Coupling (NPT, BSP, Victaulic, fixed or swivel, flange), plain cut, raised, cuffed. Others available on request. |

| Flange patterns | Flanges to all standards (custom flange patterns available on request) |

| Connection material | Hot dipped gal (as standard), Stainless steel (SS316, SS304), carbon steel, painted |

| Temp | -30/+130C |

| Safety Factor | 4:1 |

Description

Pacflotech mining hose is designed for maximum abrasion resistance against slurry materials in mining, dredging, and many other industries. Our material handling hoses use a specially formulated ABRASATECH™ tube liner which has been tested to provide the best abrasion loss in the world. We have a large range of alternative abrasion resistant liners for arduous rock applications where cut and tear resistance is required down to very fine mineral sand resistant compounds.

Pacflotech is also one of the only hose manufacturers in the world that has developed the ability to hot cure butyl tube liners into our hoses. This can provide increased chemical and temperature resistance up to 135C, whilst also maintaining abrasion resistant qualities. Compared to other butyl lined hoses on the market, ours are vulacanised into the hose which minimises any risk of the liner detaching from the hose under suction applications.

Ceramic lined

Pacflotech can also offer ceramic lined hoses which are designed for extreme wear resistance. Alumina ceramic tiles are cured into the hose lining to achieve increased wear resistance, further improving the life of the hose.